In the fight against climate change, companies and individuals are looking for innovative solutions to reduce their carbon footprints and earn carbon credits. One such approach is biochar—a sustainable product created through the process of pyrolysis, where organic materials are heated in a low-oxygen environment. This process not only helps reduce greenhouse gases but also creates valuable carbon credits.

What is Biochar and How Does it Work?

Biochar is essentially a type of charcoal that is produced by heating organic materials (like wood, agricultural waste, or even municipal solid waste) in a carbonization machine under controlled conditions. This process is known as pyrolysis, and it creates a stable form of carbon that can be sequestered in soil for hundreds to thousands of years.

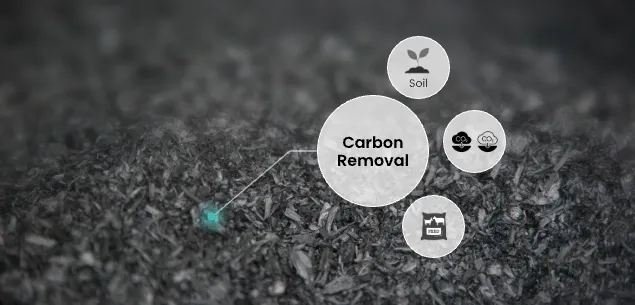

The carbonization process locks carbon in a stable form that the environment can store for long periods, making it an effective tool for reducing atmospheric carbon. This stabilization of carbon is crucial in mitigating the effects of climate change, as it prevents the carbon from being released back into the atmosphere as carbon dioxide.

How Biochar Production Earns Carbon Credits

Carbon credits are certificates that represent the reduction of one metric ton of carbon dioxide (or its equivalent in other greenhouse gases) from the atmosphere. Organizations that reduce emissions or implement carbon-capturing technologies can earn these credits.

Biochar production is one such method. When organic waste is converted into biochar, carbon that would have otherwise been released into the atmosphere through decomposition or burning is sequestered in a stable form. This makes biochar an attractive option for companies looking to earn carbon credits and offset their own carbon emissions.

By using a carbonization machine, businesses can convert waste materials into biochar, while also reducing their carbon footprint. Each ton of biochar produced can earn a corresponding amount of carbon credits, depending on the amount of carbon it sequesters. These credits can be sold in carbon markets or used to offset emissions, providing a financial return for the producer.

The Role of the Carbonization Machine in Biochar Production

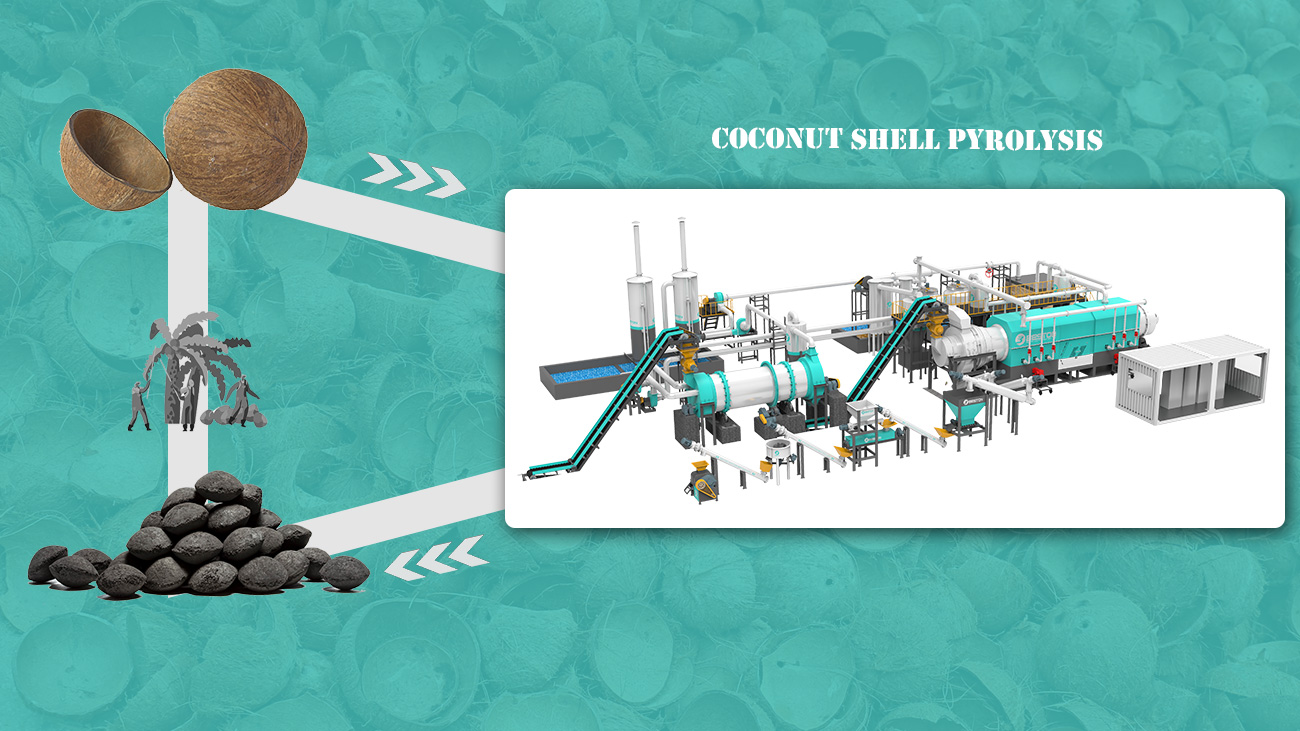

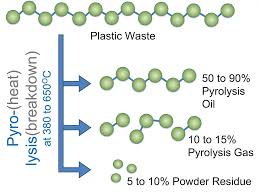

The carbonization machine is at the heart of biochar production. This specialized equipment heats organic materials in the absence of oxygen, causing them to break down into biochar, bio-oil, and syngas. The high temperature and low-oxygen environment are critical to the formation of stable carbon, which is essential for carbon sequestration.

In addition to creating biochar, the carbonization machine also generates bio-oil and syngas, which can be used as renewable energy sources. This dual-purpose technology enhances the profitability of biochar production by creating multiple revenue streams from a single process. As a result, businesses can maximize their financial returns from carbon credits and renewable energy sales.

Why Biochar is a Win-Win for the Environment and Businesses

Biochar offers a unique opportunity to address two key challenges simultaneously: reducing greenhouse gas emissions and improving soil health. For the environment, biochar provides a long-term solution to sequester carbon and reduce the impact of climate change. When applied to soil, biochar enhances nutrient retention, improves water holding capacity, and promotes soil biodiversity.

For businesses, the economic benefits are clear. Earning carbon credits from biochar production helps offset emissions, reduces the need for costly carbon taxes, and can create new revenue streams through the sale of carbon credits and renewable energy. Moreover, biochar production aligns with sustainability goals, boosting a company’s green credentials and appealing to eco-conscious consumers.

The carbonization machine is key to unlocking these benefits, providing an efficient and scalable way to convert waste into a profitable and environmentally beneficial product.

Conclusion

The process of earning carbon credits through biochar production is an exciting opportunity for businesses to contribute to environmental sustainability while generating financial returns. The carbonization machine plays a critical role in transforming organic waste into a stable form of carbon that can be stored in soil for years, offering long-term environmental benefits. For businesses, this process not only helps achieve carbon neutrality but also opens up new revenue streams through the sale of carbon credits and renewable energy.

By investing in biochar production and the carbonization machine, companies can create a win-win scenario—helping the planet while improving their bottom line. It’s a forward-thinking strategy that combines innovation, sustainability, and profitability in one powerful solution.