In the era of sustainability and environmental consciousness, the circular economy has become a key concept in promoting resource efficiency, waste reduction, and long-term environmental benefits. One of the remarkable contributions to this movement comes from coconut shell biochar, a product created through the pyrolysis of coconut shells. This biochar has not only gained recognition for its environmental benefits but also for its alignment with circular economy principles.

Let’s delve into how coconut shell biochar fits into the circular economy, driving value from waste, promoting sustainable practices, and creating a regenerative system.

Understanding Coconut Shell Biochar

Coconut shell biochar is a carbon-rich material produced by heating coconut shells in the absence of oxygen (a process known as pyrolysis). The coconut shells, which are usually discarded as waste after the coconut’s pulp is harvested, are converted into a stable form of carbon. This biochar can be used in various applications, ranging from soil improvement to energy production and even pollution remediation.

But how does it tie into the circular economy?

Coconut Shell Biochar and Waste Management

The first and most direct connection between coconut shell biochar and the circular economy is waste management. Coconut shells, a byproduct of the coconut industry, are often discarded or poorly disposed of. Instead of adding to landfill waste or being burned in open air (which causes air pollution), these shells are put through the coconut shell charcoal making machine to produce biochar.

By converting coconut shells into biochar, we are not only diverting waste from landfills but also creating a valuable product that can serve multiple purposes, thus closing the loop of waste disposal and contributing to resource recovery.

Soil Enhancement and Agriculture: A Sustainable Solution

One of the most notable applications of coconut shell biochar is in agriculture. Biochar is used as a soil amendment to improve soil fertility, water retention, and microbial activity. This aligns with circular economy principles by:

- Enhancing soil health: Biochar can be applied to poor-quality or degraded soils, improving their productivity, and reducing the need for chemical fertilizers.

- Reducing carbon footprint: As biochar is stable in the soil, it acts as a long-term carbon sink, storing carbon for hundreds or even thousands of years, thereby helping mitigate climate change.

Through coconut shell biochar, we essentially recycle carbon that would have been emitted into the atmosphere from burning or decomposing coconut shells. This helps create a more sustainable agricultural system that relies on natural processes rather than synthetic inputs.

Energy Recovery and the Circular Economy

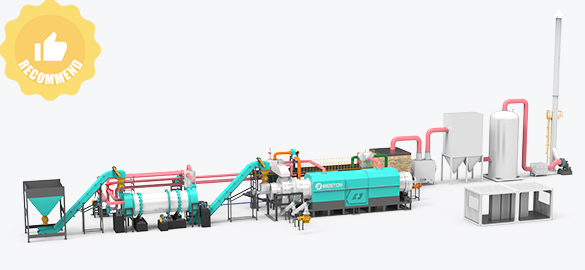

In addition to its use in agriculture, coconut shell biochar plays an important role in energy recovery. The pyrolysis process that creates biochar from coconut shells also generates syngas (synthetic gas) and bio-oil, which can be used as alternative energy sources. The coconut shell charcoal making machine is a key technology in facilitating this process.

By extracting energy from coconut shells in the form of gas and oil, we are effectively turning waste into valuable energy, supporting a renewable energy cycle. This energy can power homes, industries, or even the pyrolysis equipment itself, creating a self-sustaining system that reduces dependence on fossil fuels.

Carbon Sequestration and Climate Mitigation

A crucial principle of the circular economy is the emphasis on carbon neutrality and reducing environmental impact. Coconut shell biochar plays an important role in carbon sequestration. When biochar is buried in soil, it locks away carbon for hundreds to thousands of years, preventing it from re-entering the atmosphere as carbon dioxide. This contributes to climate change mitigation by reducing greenhouse gas concentrations in the air.

This is particularly important in the context of the coconut shell biochar production process. By using coconut shells—a natural, renewable material—as a feedstock for biochar production, we reduce the overall carbon footprint compared to fossil fuel-based products.

Supporting a Circular Economy with Technology: The Role of Charcoal Making Machines

The process of creating coconut shell biochar involves advanced coconut shell charcoal making machine that ensure efficient and sustainable production. These machines enable the pyrolysis of coconut shells in a controlled environment, minimizing energy consumption and emissions. They also produce byproducts like syngas and bio-oil, further supporting the circular economy by ensuring that no part of the coconut shell goes to waste.

By investing in such technology, industries can not only reduce waste but also generate valuable products, contributing to the broader goals of the circular economy—where waste is minimized, resources are regenerated, and systems are self-sustaining.

Commercial Viability and the Circular Economy Model

The production of coconut shell biochar is not just an environmental initiative; it has economic benefits as well. The sustainable production of biochar from coconut shells opens up new business opportunities in both the agriculture and energy sectors. Biochar products can be sold to farmers, landscapers, or energy producers, creating a profitable market while simultaneously reducing waste and promoting sustainability.

The circular economy model is built around the idea of creating value from waste, and coconut shell biochar is a perfect example of how we can generate economic profit while protecting the environment. In this model, businesses that manufacture coconut shell charcoal making machines contribute to the creation of a more sustainable economy by providing the tools to efficiently convert waste into valuable products.

Conclusion: A Step Towards a Sustainable Future

Coconut shell biochar is a prime example of how circular economy principles can be applied to the natural world. From waste management and energy recovery to carbon sequestration and agricultural enhancement, biochar produced from coconut shells offers multiple environmental, economic, and social benefits.

By leveraging technologies like the coconut shell charcoal making machine, we can make the production of biochar more efficient and scalable, supporting a circular economy that reduces waste, conserves resources, and mitigates climate change.

As we move towards a more sustainable and regenerative future, coconut shell biochar offers a tangible solution for turning waste into value while benefiting both the environment and the economy.