Plastic waste management is a pressing global issue, and pyrolysis is a chemical process that converts plastics into oil, gas, and carbon residue. While equipment like the Beston plastic pyrolysis plant is widely referenced, the key focus should be on the underlying principles and reactions rather than specific brands.

Pyrolysis Principles

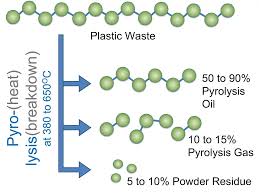

Plastic pyrolysis involves thermal decomposition in an oxygen-limited environment. High molecular weight polymers break down into smaller organic molecules at temperatures typically between 350–500°C. The type of plastic (PE, PP, PS, etc.) significantly influences the distribution of liquid oil, gas, and solid carbon.

Process Overview

- Feedstock Preparation: Waste plastics are sorted, cleaned, and shredded to remove impurities and ensure uniform heating. PVC and plastics with halogens should be avoided due to toxic gas formation.

- Pyrolysis Reaction: Plastics are heated in a reactor. Thermal cracking converts long polymer chains into volatile hydrocarbons.

- Condensation and Collection: The resulting vapor is cooled and condensed into liquid fuel, while non-condensable gases may be reused as fuel for the heating system.

- Carbon Residue Handling: The solid fraction left after pyrolysis, often called char or carbon black, can be processed further or used in industrial applications.

Key Considerations

- Controlling temperature and residence time is critical for optimizing liquid yield.

- Preprocessing ensures consistent feedstock and reduces contamination.

- Proper gas treatment is essential to prevent environmental pollution.

Applications and Implications

Pyrolysis provides a method to recover energy from plastic waste, producing usable fuels and materials while reducing landfill pressure. Understanding the reaction mechanisms and process parameters allows for improved product quality, higher yield, and reduced environmental impact.

Conclusion

While plastic pyrolysis is fundamentally a chemical and thermal process, equipment design significantly influences efficiency, yield, and safety. For example, systems like the Beston plastic pyrolysis plant are engineered to provide controlled heating, effective condensation, and safe handling of byproducts, which can improve operational consistency and environmental performance. Studying such equipment allows researchers and operators to better understand process optimization, reactor design, and waste-to-energy conversion, without focusing on branding or commercial promotion. Ultimately, the principles remain the same: converting plastic waste into usable fuels and carbon materials through careful temperature and residence time management.

Leave a Reply