Plastic waste has become one of the most pressing environmental challenges of our time. Globally, millions of tons of plastic end up in landfills and oceans each year, posing serious threats to ecosystems and human health. While recycling helps, a significant portion of plastic waste is non-recyclable through conventional methods.

Pyrolysis technology offers a promising solution: converting waste plastics into valuable fuel, simultaneously addressing environmental pollution and energy demand.

What Is Plastic Pyrolysis?

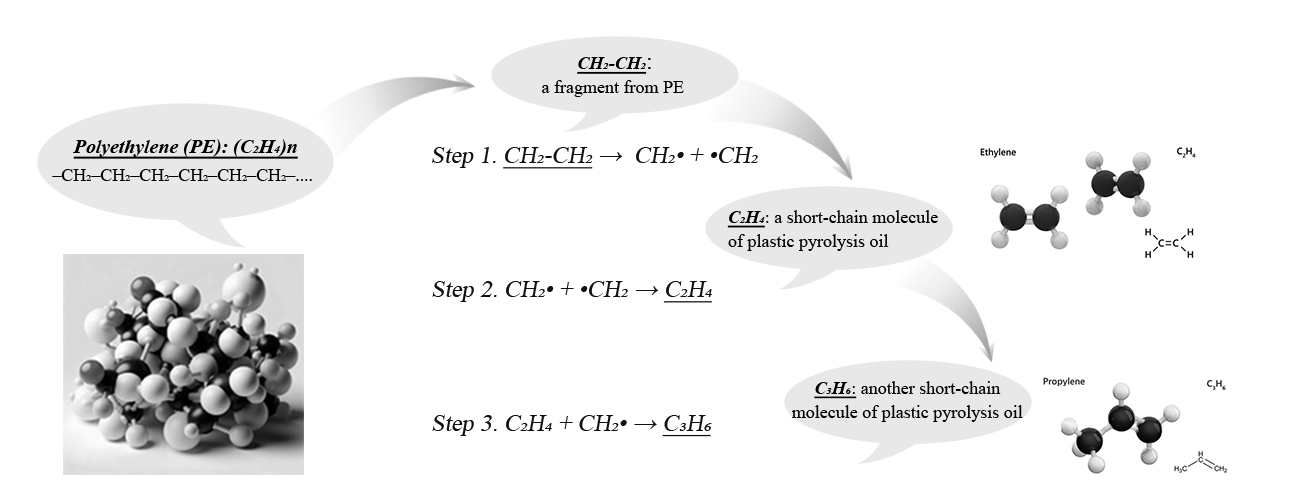

Plastic pyrolysis is a thermochemical process in which plastic materials are heated in the absence of oxygen, breaking long polymer chains into smaller molecules. The primary outputs of plastic pyrolysis are:

- Pyrolysis oil (liquid fuel): Can be used directly as fuel or refined into diesel, gasoline, or other chemical feedstocks.

- Syngas: A combustible gas mixture that can be used to power the pyrolysis process itself or generate electricity.

- Char (solid residue): Can be used as a carbon additive or in construction materials.

Applications and Market Potential

Plastic pyrolysis plants are increasingly adopted worldwide, particularly in regions struggling with plastic waste management. Applications include:

- Industrial and municipal waste management

- Production of diesel, gasoline, and other liquid fuels

- Supplementing energy for industrial operations

- Circular economy initiatives by turning waste into valuable products

The global push for sustainability and renewable energy makes plastic-to-fuel pyrolysis a rapidly growing sector with significant investment potential.

Conclusion

Plastic pyrolysis is more than just waste management — it’s a bridge between environmental responsibility and energy production. By transforming plastic waste into fuel, industries and governments can simultaneously tackle pollution and generate renewable energy, contributing to a cleaner and more sustainable future.

Leave a Reply